المنتجات الساخنة

Modernizing cement manufacturing in China leads to

网页2022年11月17日 At the same time, cement manufacturing technology has been upgraded rapidly. (NSP) rotary kilns. Before 2000, shaft kilns were the dominant CMT due to the

Contact

Cement Plant, Cement Equipment Cement Plant Manufacturer

网页Our Production Equipment. AGICO Cement is a cement plant manufacturer with production capacity of 30,000 tons of equipments and structure parts and 20,000 tons of casting

Contact

Cement Equipment In Cement Plant AGICO Cement Plant

网页Cement Equipment Supplier. AGICO Cement is located in Henan, China. It was founded in 1997 with a registered capital of 81.34 million yuan. It covers an area of 660000m 2

Contact

Cement Euipment Overview Cement Making Machines Cement

网页2019年9月27日 Cement mill is another necessary cement equipment of the cement plant. After raw material crushing, cement mill plays vital role in the further cement

Contact

Cement Manufacturing Plant Cement Plant AGICO EPC Cement

网页AGICO is a professional cement equipment and cement manufacturing plant supplier in China. We have more than 20 years’ experience in constructing cement EPC projects at

Contact

Cement Equipment, Cement Plant Equipment Cement Plant Manufacturer

网页We provide customers with a variety of cement plant equipment and optimize the combination of various types of cement grinding mill to meet the needs of different

Contact

What Equipment is Used for Cement Manufacturing? Prater

网页2023年7月19日 Because raw coal is still used in cement manufacturing, equipment that can grind coal onsite is necessary for most cement plants. As with the actual milling of

Contact

Cement Manufacturing Equipment for Sale AGICO Cement

网页Cement Manufacturing Equipment. PRODUCTS. Raw Meal Preparation. Cement Crushers. AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher,

Contact

Cement Manufacturing Process: 6 StepsTo Make

网页2020年1月27日 6 steps of the cement manufacturing process. When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one

Contact

Cement Production Line Cement Manufacturing Plant AGICO Cement

网页AGICO dry process cement production line comprehensively adopts the IT technology, multi-function grinding system, new-type wear-resisting and heat-resisting materials,

Contact

Volume 3, Issue 5, November 2013 Study of Processing

网页2014年1月14日 result, wet cement is strongly caustic and can easily cause severe skin burns if not promptly washed off with water. Similarly, dry cement powder in contact with mucous membranes can cause severe eye or respiratory irritation. II. STAGES OF CEMENT MANUFACTURING Stage-1.Opencast lime stone mining

Contact

Cement Equipment In Cement Plant AGICO Cement Plant

网页Cement Equipment Supplier. AGICO Cement is located in Henan, China. It was founded in 1997 with a registered capital of 81.34 million yuan. It covers an area of 660000m 2 which includes a construction area of 30000 m 2. In 2004, AGICO passed the ISO9001 certification and enjoyed the self-management right of import and export.

Contact

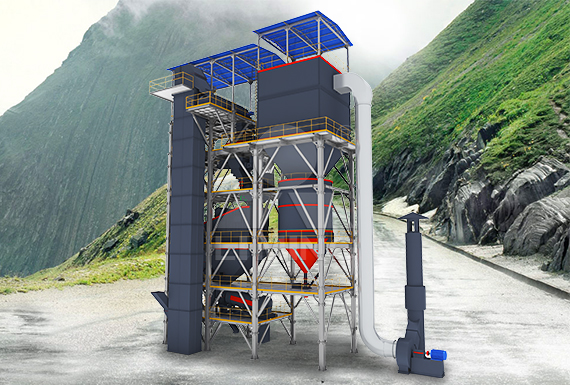

Cement Plant Cyclone Preheater Equipment Supply

网页AGICO Cement Preheater Features. Our cyclone preheater adopts a multi-stage circulation suspension preheating mode, and has a high production efficiency. The preheating temperature in the cyclone preheater can

Contact

Cement Equipment, Cement Plant Cost AGICO Cement Plant Manufacturer

网页There are generally 5 aspects you may concern: cement equipment, cement manufacturing process, cement plant manufacturer, cement plant benefits, and related service. AGICO CEMET is a cement plant manufacturer with rich experience from China. We can provide a one-stop EPC solution for your cement plant, including all cement equipment, design

Contact

Cement Plants Cement Plant Equipment, Rotary Kiln Cement

网页50 TPD-1000 TPD. Cement Plants- with Vertical Shaft Kilns. 50 TPD-300 TPD. Cement Plants- with Rotary Kilns. 200 TPD-1000 TPD. Individual equipment and components such as jaw/hammer crushers, ball mills, ball mill drives, kilns, conveyors, elevators, feeders, blower's etc. Spare parts such as gears, gear reducers, tyres, rollers, mill headers etc.

Contact

Cement Machinery Cement Making Machine

网页Semi-automatic cement manufacturing machine service, capacit Cement manual bag feeding machine, capacity: 20 ton 25 ton Cement spreader machine. Cement spreader. Manual cement feeding system, capacity: 36

Contact

Cement Extraction, Processing, Manufacturing

网页cement Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the

Contact

Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

网页It is because that the price of cement manufacturing equipment is relative to their capacities. Cement equipment with higher capacities generally is more expensive. And because the construction process of mini cement plants is simpler, the labor cost is also lower than medium and large-scale cement plants. Quick Building

Contact

Cement Manufacturing Process INFINITY FOR

网页As Clinkerization process is an endothermic (heat absorbing) process it requires burning of Suitable fuel. Remember almost 40 % of the total cost spent for manufacturing cement is for fuel and power. The specific heat

Contact

Cement Manufacturing Machine Cement Plant

网页A cement mill is just a general term for clinker grinding mill. It is a kind of grinding equipment that used to grind the calcined cement clinker then make them reach the particle fineness requirement of the finished cement

Contact

Cement Bag Filling Machine AGICO BGYW Cement Inline

网页Featuring accurate weighing, stable performance, reasonable structure, simple operation, and durable parts, the AGICO BGYW cement filling machine is fully capable of bagging cement and other powdery materials. For cement plants whose daily packaging volume is less than 1200t/d, it is more economical to choose two 3-spout inline cement filling

Contact

Cement Plants Thomasnet

网页2023年7月15日 Erie, PA Manufacturer* $25 49.9 Mil 1913 100-199. Manufacturer of concrete mixers and mixing plants. Mobile, portable, and stationary mixing plants are available for construction, paving, and ready-mix applications. Concrete mixers are hydraulically-powered with 6, 9, 12 or 15 cubic yard sizes available.

Contact

Rotary Cement Kiln Manufacturer AGICO Cement Plant

网页1. Our rotary cement kilns are all made of thermal insulation material, which reduces the radiation heat loss and energy consumption during the burning process; 2. We use the compound fish scale to soft seal the front end and the back end of the rotary cement kiln. The air leakage coefficient can be thus controlled less than 10.

Contact

Fly Ash Processing Plant Cement Equipment Manufacturing

网页The fly ash processing plant constructed by AGICO Cement is highly automated and mechanized, with low investment, high profit, simple structure and easy operation, which helps each region realize reasonable waste recycling and utilization to ‘green up’ users’ supply chains. Raw Material. Fly Ash / Volcanic Ash. Capacity (t/h) 8-11. 11-14

Contact

How To Measure Your Cement Mill And Cement Classifier? AGICO CEMENT

网页2020年12月1日 With the increase of cement mill specifications and the requirement of energy saving, high yield, and high quality of cement grinding plant, the closed-circuit grinding is an inevitable trend of cement grinding unit.The essential equipment of a closed-circuit grinding system is a cement classifier, also known as a cement separator.The

Contact

Parametric Studies of Cement Production

网页The cement industry is one of the most intensive energy consumers in the industrial sectors. The energy consumption represents 40% to 60% of production cost. Additionally, the cement industry contributes around 5%

Contact

Cement Manufacturing Process Chemical

网页2020年9月26日 Cement Manufacturing Process:- ement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances.. Both the materials are then channeled

Contact

The Cement Manufacturing Process Thermo

网页2015年8月20日 Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation

Contact

PPC Cement Manufacturing Process Portland

网页Portland pozzolana cement is suitable for concrete works underground, in water, or humid environment, especially for projects requiring impermeability, freshwater resistance, and sulfate corrosion resistance,

Contact

How Cement is Made Cement Manufacturing Process

网页2023年7月12日 Stage of Cement Manufacture. There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite. The ore rocks are quarried and

Contact