المنتجات الساخنة

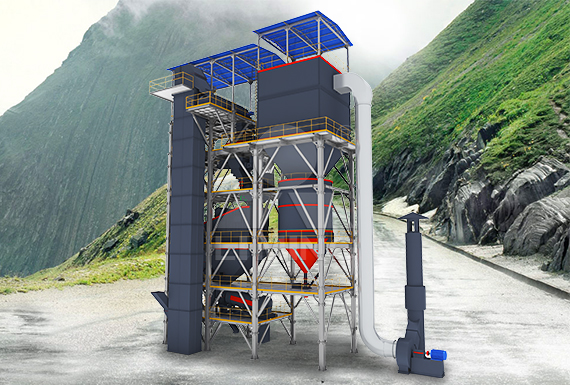

STEAM FLAKING UNITS Yemmak

网页2021年2月23日 DIMENSIONS A B C SCT 5 SCT 10 1500 1500 3000 6500 8500 10 2500 5000 5 1000. SPECIFICATIONS • High quality rollers • Heavy duty roller bearings Flaking roller mill mostly used for ˜aking steam annealed small sized cereals. Spacing

Contact

Flaking Mill DOQB Group PDF Catalogs Technical

网页Reliable and efficient flaking. DOQB Dimensions A mm Roll Dimensions Diameter mm Length mm Roll Pressure Force kN Mode of operation. The raw material is homogenized

Contact

FLAKING ROLLER MILL Yemmak

网页2022年1月7日 Flaking roller mill mostly used for flaking steam annealed small sized cereals. Spacing between heat-strenghtened, corrosion-proof roller balls are adjustable.

Contact

Flaking roller mill type FWS StreckelSchrader

网页The flaking roller mill is a versatile yet compact processing device for your flaking line. The feeding roll is integrated into the upper section of the roller mill, which saves you up to 60 cm of installation height. Dimensions.

Contact

Flaking Roller Mill POLYfloc? BCFA Group PDF

网页Flaking roller mill with Steamer Fine -grade flakes of consistent quality Mode of operation The product to be flaked is fed from the feed hopper into the steaming zone

Contact

Flaking Roller Mill SCHULE Mühlenbau schule

网页The high-performance SCHULE flaking roller mill is the core of our flaking line. Efficient and gentle flaking of the respective products is achieved thanks to the ideally adjusted gap

Contact

en/flaking roller dimensions.md at main lbsid/en

网页Contribute to lbsid/en development by creating an account on GitHub.

Contact

Flaking failure in rolling contact fatigue caused by

网页2002年5月1日 Flaking failures occurred on the defect-free small roller surfaces on 35 of the 37 tests. The only exceptions were nos. 2 and 3. As the top and cross-sectional views in

Contact

Flaking Roller Mills Crusher Mills, Cone Crusher, Jaw Crushers

网页Used Flaking Mills. One (1) “Used As Is” Excellent Condition liming (made in Switzerland) Flaking Mill 600×1250 Heavy carbon steel construction, . Ross Roller Mill 18 X 24 (Flaker)

Contact

Flaking roller mill with Steamer m.sanitaryindustry

网页2016年7月15日 Flaking roller mill with Steamer BCFA, MBDA AG CH-9240 Uzwil, Switzerland T +41 71 955 11 11 F +41 71 955 66 11 group Technical

Contact

Flaking Mill DOQB Group PDF Catalogs Technical

网页Reliable and efficient flaking. DOQB Dimensions A mm Roll Dimensions Diameter mm Length mm Roll Pressure Force kN Mode of operation. The raw material is homogenized in the mixer and with the assistance of regulable feed roll equally distributed into the roll gap. Big sized and surface treaded rolls assure an optimal flaking of product.

Contact

Flaker ZWG Bauermeister Size Reduction Equipment

网页Flaker ZWG 600.1, 700800. Flakers are utilized in the oilseed industry to convert pre-crushed oil seeds into flakes for the subsequent extraction process. Bauermeister Flakers ZWG come in different sizes for various throughputs. A variable flaking gap as well as roll pressure (between 50 and 80 bar) allows flexible adjustment of the Flaker

Contact

Flaking Roller Dimensions

网页2020年9月14日 Flaking Roller Crusher varlet-bertrand-avocat.fr Sizes Available: Rolls Ferrellross White structure flaking (WSF) as a premature wear failure mode in steel rolling element bearings is caused by white etching cracks (WECs) and perhaps butterflies formed in the ~1 mm zone beneath the contact surface under rolling contact fatigue (RCF).

Contact

STEAM FLAKING UNITS Yemmak

网页2021年2月23日 DIMENSIONS A B C SCT 5 SCT 10 1500 1500 3000 6500 8500 10 2500 5000 5 1000. SPECIFICATIONS • High quality rollers • Heavy duty roller bearings Flaking roller mill mostly used for ˜aking steam annealed small sized cereals. Spacing between heat-strenghtened, corrosion-proof roller

Contact

Fault diagnosis method of rolling bearing using principal

网页2018年12月7日 To effectively extract the fault feature information of rolling bearings and improve the performance of fault diagnosis, a fault diagnosis method based on principal component analysis and support vector machine was presented, and the rolling bearings signals with different fault states were collected. To address the limitation on effectively

Contact

2022/sbm flaking roller s.md at main naicha22/2022

网页Contribute to naicha22/2022 development by creating an account on GitHub.

Contact

Flaking Mills SP 2800 |CPM

网页Roskamp flaking mills feature quality construction and materials throughout. The unique Roskamp flaker square-bearing housing design assures accurate, consistent flaking and ease of operation. Double-row

Contact

sbm/sbm flaking roller mill dimension.md at master sbm

网页You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Contact

Manual Furlex 200 S 300 S Selden

网页2015年3月20日 3.3.1 Dimensions of lower bearing assembly 10 3.3.2 Dimensions of top eye terminal 10 3.3.3 Table of measurements for toggles 11 3.4 Assembly below deck 12 3.5 Calculating the length of the forestay wire 13 3.5.1 Table 1: Calculation of forestay wire length 13 3.6 Calculating the length of the luff extrusion 14

Contact

2022/sbm flaking roller machinery.md at main naicha22/2022

网页Contribute to naicha22/2022 development by creating an account on GitHub.

Contact

Flaking Roller Mill SCHULE Mühlenbau schule

网页The high-performance SCHULE flaking roller mill is the core of our flaking line. Efficient and gentle flaking of the respective products is achieved thanks to the ideally adjusted gap and individually adjusted heat of the rollers. The obtained flakes are uniformly dried and cooled down to ambient temperature by means of the downstream fluidised

Contact

Particle Size and Standard Deviation CPM

网页2022年4月15日 Roller Mill Equipment Description Roller mills are commonly referred to by the type of service they perform. A mill used to crack grain or other types of friable materials may be called a cracking mill. Mills used to flake grains or other products may be called flaking mills or flakers. Roller mills used to grind in a feed mill are

Contact

Tapered Roller Bearings The Timken Company

网页Inch Single Row. Single-row tapered roller bearings are the most basic and widely used, consisting of a cone assembly and a cup. Timken patented the first in 1898 and today offers the world's widest variety in inch and metric

Contact

Effects of Axial Clearance on Surface Initiated Flaking in

网页2023年1月17日 First, rotating tests were conducted on combination tapered roller bearings with dented raceways under several axial clearances different from the standard condition. Second, the surface profiles of the bearings before and after the tests were compared to investigate the relationship between the distribution of flaking area and the axial clearance.

Contact

Conveyor belt flaking roller and system Google Patents

网页US3712100A 1973-01-23 Method and system for laying a pipeline from a reel barge. EP3137801A1 2017-03-08 Marine reel lay method pipeline installation vessel and methods. EP3733562B1 2022-01-19 Conveyor belt flaking roller and system. KR101019909B1 2011-03-08 Apparatus for generating a round sling and the method thereof.

Contact

China Flaker Mill, Flaker Mill Manufacturers, Suppliers, Price

网页Precooked Corn Flour Mill Flaking Roller Mill for South America . US$ 59888-197888 / Piece. 1 Piece (MOQ) Roll Dimensions : 800X1600mm; Main Motor Power : 110kw; Flake Thickness

Contact

Flaking Roller Mill POLYfloc? BCFA Group PDF

网页Flaking roller mill with Steamer Fine -grade flakes of consistent quality Mode of operation The product to be flaked is fed from the feed hopper into the steaming zone located in the upper section of the steamer. A special steam distribution system directs saturated steam to several points in the product and distributes it uniformly.

Contact

Conveyor belt flaking roller and system Google Patents

网页Conveyor belt flaking systems include a plurality of conveyor belt segments, each of the segments having opposing splice-able distal ends, a cable winch positioned proximate to a first end of the conveyor belt flaking system and at least one of the plurality of conveyor belt segments positioned proximate an opposing second end of the flaking system, a plurality

Contact

Machines Free Full-Text Failure Analysis of a Cylindrical Roller

网页2022年4月29日 The premature failure of a cylindrical roller bearing took place during service, with a total operation time of 100 h. The failure cause was analyzed by macroscopic and microscopic observation, metallographic analysis, hardness testing, tightening axial force influence analysis, and test verification. The results show that failure modes of the

Contact