المنتجات الساخنة

A new model-based approach for power plant Tube-ball mill

网页2014年4月1日 The mill model is running in parallel with the power plant coal mill operation; the measured and predicted outputs are displayed on the computer screens in the power plant control room. When the measured and predicted mill outputs are over the pre-set

Contact

Fuzzy Control of Ball Mill for Pulverizing System of Thermal Power Plant

网页1997年8月1日 I Operation characteristics ofthe ball mill ® Q) ® III Fig. 2 Operation characteristics of the ball mill In Fig.2 the relation between the power input to the driving

Contact

OPTIMIZATION OF CEMENT GRINDING OPERATION IN

网页2021年4月27日 Operation and Elements of a Closed-Circuit Ball Mill System . Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter

Contact

Ball Mill an overview ScienceDirect Topics

网页Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used

Contact

The operating principle of the ball mill

网页2017年2月8日 The disadvantages of ball mills include their considerable metal consumption and deterioration grinding media, as well as a lot of

Contact

Pulveriser in Thermal Power Plant Bowl Mill Ball

网页2023年7月19日 Operation of Ball Mill Pulveriser. The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

Ball Mill Design/Power Calculation 911 Metallurgist

网页2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired

Contact

Ball Mill Operation -Grinding Circuit StartupShutdown Procedure

网页2016年2月1日 Normal Shutdown Sequence of Ball Mill and Grinding Circuit. Shut off cyanide metering pump. Put weight controller into MANUAL mode and turn controller

Contact

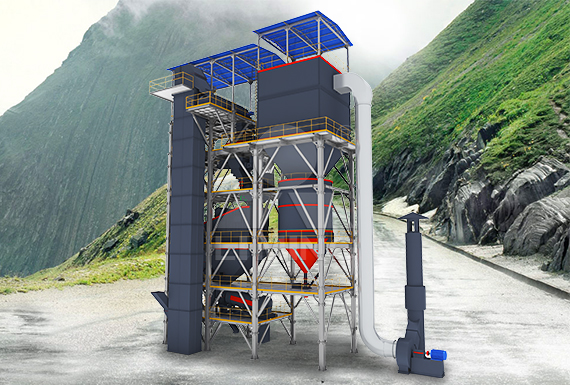

BALL MILL PLANT Laxmi Engineering

网页BALL MILL PLANT. BALL MILL WITH CLASSIFIER UNIT. Staying tuned up with time and technology for over 40 years; we at LEW aspire to give our customers best solution,

Contact

The operating principle of the ball mill

网页2017年2月8日 The disadvantages of ball mills include their considerable metal consumption and deterioration grinding media, as well as a lot of noise. Most of the energy useless lost during ball mill operation, leading

Contact

Coal Pulverizer Power Plant Pall Corporation

网页2 天之前 Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal,

Contact

(PDF) Rod Mill Product Control and Its Relation to

网页2022年1月30日 A laboratory-scale tumbling rod mill was designed for this study, and six operative parameters were tested and analyzed in order to detect the main influences on the mill product, attending to

Contact

Tubular Rod Mills ScienceDirect

网页2016年1月1日 As the considerations of rod mills are similar to the ball mills, some of the problems given below require the use of formulae described for ball mill operations in Chapter 7. 8.1. The inner dimensions of a rod mill were 1.8 × 1.8 m and the largest diameter of rod charged was 76 mm. The mill consumed per tonne of rods was 25 kW/t.

Contact

Thermal power plant ball mill load soft-sensing method

网页Pulverized coal preparation system is one of main backup system of fuel-burning power plant, because barrel-shaped steel ball mill is the strongest to the adaptability of coal, is domestic most widely used a kind of coal pulverizer.Coal pulverizer is the key equipment of pulverized coal preparation system, and can it normally move and whether operate in

Contact

Energy-Efficient Technologies in Cement Grinding

网页2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Contact

Raw Material Drying-Grinding Cement Plant Optimization

网页Roll presses are also used in, particularly in upgrading existing ball mill circuits as pre-grinders to increase production or to reduce specific power consumption in grinding operation. Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2.5-3.5M/sec above the ball charge), can

Contact

Coal Mill an overview ScienceDirect Topics

网页The analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only. As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill operations will be based on this mill type. Figure 13.2 illustrates the typical key components of a VSM.

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

PROCESS CONTROL FOR CEMENT GRINDING IN

网页2017年10月27日 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and

Contact

AMIT 135: Lesson 7 Ball MillsCircuits Mining

网页At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain

Contact

Grinding in Ball Mills: Modeling and Process Control

网页Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Contact

3 Common Problems and Solutions in Ball Mill

网页2020年6月24日 The stable operation of equipment is an important way to ensure the economic benefit of mineral processing plants. Due to long-term operation, ball mills of most mineral processing plants will cause various

Contact

Coal Mills in Thermal Power Plant PDF Mill (Grinding)

网页2023年6月24日 Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill. Beater Mill or Fan Mill. TYPES OF MILL Tube or ball mills: These are low-speed machines that grind. the coal with steel balls in a rotating horizontal cylinder. If the

Contact

sbm/sbm ball mill operation power plant.md at main GitHub

网页Contribute to changjiangsx/sbm development by creating an account on GitHub.

Contact

Ball Mill Design/Power Calculation 911 Metallurgist

网页2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired

Contact

Coal Grinding Cement Plant Optimization

网页Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe

Contact

Analysis of noise and vibration during the

网页Analysis of noise and vibration during the operation of the ball mill The ball mill is used for grinding materials after crushing, and CHAENG is a professional manufacturer of ball mill accessories, such as girth gear of

Contact

(PDF) Improving the efficiency of the coal grinding

网页2022年2月24日 Ensuring the reliable operation of the dust fuel preparation system at thermal power plants (TPP) is a topical issue since it determines the energy strategy of any country that fires coals for

Contact