المنتجات الساخنة

Cement Directory: Mini Cement plants International Cement

网页HENAN SRON® SILO ENGINEERING CO., LTD. +86-371-63253880 F10, Xin'ao Plaza, No.2 of Commerce Inner Loop road, Jinshui district, Zhengzhou, Henan, China 450000

Contact

How to Start a Mini Cement Plant entrepreneurindia.co

网页2022年7月21日 The Indian cement industry is dominated by a few companies. The top 20 cement companies account for almost 70 per cent of the total cement production of the

Contact

Cement Extraction, Processing, Manufacturing

网页cement Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the

Contact

Cement Manufacturing Process: 6 StepsTo Make

网页2020年1月27日 6 steps of the cement manufacturing process. When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one

Contact

How to Start a Mini Cement Plant. Cement Manufacturing Industry. Cement

网页Cement is indispensible for building and construction work and cement industry is considered to be an important infrastructure core industry. It is one of the most advanced

Contact

How Is Cement Produced in Cement Plants Cement Making Process

网页Phase IV: Calcination. The calcination is the core phase of the cement making dry process. The calcination of the preheated raw meal takes place in the rotary kiln of the cement

Contact

How to Start a Mini Cement Plant. Cement Manufacturing Industry. Cement

网页2018年4月21日 565.75. It accounts for 6.9% of the world’s cement output. India’s cement production capacity is expected to reach 550 million tonnes by 2025. The industry

Contact

Mini Cement Plant Manufacturing Plant, Detailed Project

网页There has been a bright scope in setting up mini-cement plant. Indian Government is providing a scheme of soft loans to current units wishing to convert from wet to dry. With

Contact

en/mini cement plant process.md at main jidafang2022/en

网页Contribute to jidafang2022/en development by creating an account on GitHub.

Contact

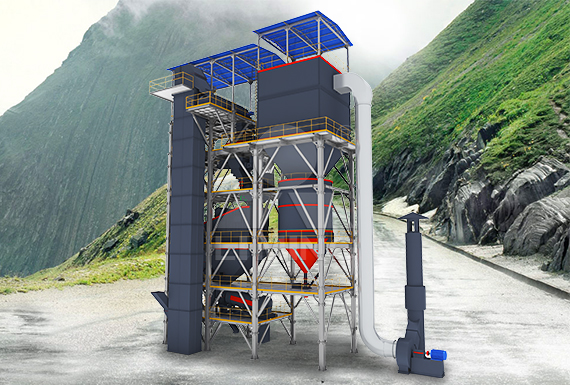

Cement Plant Clinker Grinding Plant

网页Voltage. 380 V. Process Used. Semi-Dry Process. We are leading cement plant manufacturers from India.The technology that we introduce has its own merits. The Mini Cement Plant has the production capacity of 50 tons per

Contact

How to Start a Mini Cement Plant. Cement Manufacturing Industry. Cement

网页Cement is indispensible for building and construction work and cement industry is considered to be an important infrastructure core industry. It is one of the most advanced industries of India. In a developing country like India, the cement industry can play a significant role in the overall economic growth. •Building (floors, beams, columns

Contact

How Much Does It Cost To Start A Cement Plant?

网页2020年5月14日 Today we’ll discuss the first part- cement factory cost ( or cement plant cost). According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One

Contact

mini cement plant, mini cement plant price, suppliers,

网页Get mini cement plant, mini cement plant price, suppliers, manufacturers, wholesalers, dropshippers, agents, distributors from MachineryOffers Voltage: 380V or according to customer; Place of Origin: Henan China; Product name: Professional cement plant machines process/cement production line; Weight: According to different model; Power: 800

Contact

Cement Manufacturing Process: 6 StepsTo Make

网页2020年1月27日 6 steps of the cement manufacturing process. When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one

Contact

How to Start a Cement Factory AGICO Cement Plant

网页1. Clarify Your Production Scale and Cement Type. The first thing to do when you are planning to start a cement factory is to determine which type of cement you are going to produce and how many tons you are going to produce per day. The most widely used cement for concrete works is ordinary portland cement (OPC), apart from that, there is

Contact

Exposure effect to cement dust pollution: a mini

网页2019年11月8日 The aim of this stone is to illuminate the impacts of cement production emissions on the environment. Various research work has shown that countries in sub-Saharan Africa, suffer the most from environmental

Contact

Mini Cement Plant Project Report Space

网页2023年7月2日 Mini Cement Plant Process and Technology:- In Detailed Project Report Here we cover Commercial Mini Cement Plant Process, Technology and its formulation. Latest Proven Process and Technology

Contact

Project Report on mini cement plant Manufacturing Process

网页Detailed Project Report (DPR) includes Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials. comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of

Contact

Cement Plant Manufacturers Cement Plant Equipment Turnkey Plant

网页Cement Plant Manufacturers: We Ashoka offers Turnkey Cement Plants, Cement Process Equipment, Cement Process Machinery. For details call +919811141400 or write us at ag@ashokaengineering We are manufacturers, providers and exporters of all type of cement plantequipment like Mini Cement Plant Manufacturer, Cement Ball Mills,

Contact

Small-Scale Production of Portland Cement PDF Scribd

网页2017年11月13日 Three different types of mini-cement plants are in operation: (a) Mechanized vertical-shaft kilns the annual plant capacity ranges from 50,000 to 500,000 tons and single VSK lines are of capacities 140 to 240 tpd of clinker production. As many as 2600 mini-cement plants of this type have been put into operation. Old shaft kilns of

Contact

300tpd new dry process cement plant Machine Business

网页Cement production line process is as follows: 1. crushing and preblending. 2. raw material preparation. 3. raw materials homogenization. 4. preheating and precalcing. 5. burning cement clinker in a rotary kiln. 6. cement grinding. 7. cement packaging. Packaging Detail:standard packing or nude packing,as customer's requirement.

Contact

Mini Cement Plant, Automatic Grade: Semi

网页Cement Manufacturing. Voltage. 380 V. We are leading cement plant manufacturers from India.The technology that we introduce has its own merits. The Mini Cement Plant has the production capacity of 50 tons per

Contact

en/mini cement plant process.md at main jidafang2022/en

网页Contribute to jidafang2022/en development by creating an account on GitHub.

Contact

Stacker And Reclaimer Cement Plant Parts

网页Working principle of stacker and reclaimer. Stacking process: The material is transported from the outside to the spherical silo through the trestle conveyor, and is transferred to the boom conveyor of the stocker through

Contact

Cement Plants Turnkey Cement Plants

网页PLC (programmable logic control) We are leading manufacturer and exporter of VSK Portland Cement Plants and our product is made up of good quality. The VSK technology is used for the production of small

Contact

Mini Cement Plant, Automation Grade: Automatic

网页Nilkanth Engineers Offering Mini Cement Plant, Automation Grade: Automatic at Rs 100000000/piece(s) in Rajkot, Gujarat. Also find Mini Cement Plant price list ID: 4116592891

Contact

Mini Cement Plant for Sale Small Cement Production Line

网页Rotary Kiln. Rotary kiln is the most favorable cement kiln for new dry process cement plants, it is the place where the raw materials are calcined and burnt to cement clinker. The rotary kiln ensures that the raw materials are calcined into qualified clinker within the time of passing through, and achieves the purpose of high yield, high quality, and low energy

Contact

100-300TPD Complete Cement Making Plant Equipment

网页Cement production line process is as follows: 1. crushing and preblending. 2. raw material preparation. 3. raw materials homogenization. 4. preheating and precalcing. 5. burning cement clinker in a rotary kiln. 6. cement grinding. 7. cement packaging. Packaging Detail:standard packing or nude packing,as customer's requirement.

Contact

Comparative Performance Analysis of Semi

网页2005年12月28日 for mini-cement plant [1]. The packing process using this. machine is semi-automatic because of operator’s . handling, where the empty cement bags are attached to . the filling spouts manually.

Contact