المنتجات الساخنة

Comminution and classification technologies of iron ore

网页2022年1月1日 Rio Tinto Iron ore processing plants in the Pilbara region of Western Australia do not involve any chemical treatment. Flow sheets for the Brockman 2 (8.7 MTpa) Due to soft nature of the ore product from the primary mill undergoes two stages of

Contact

Comparing strategies for grinding itabirite iron ores in

网页2021年3月15日 The rate of ore addition was dictated by the need to maintain the mill at a constant total weight, which was measured by the loadcell mountings and shown on a

Contact

Optimization of Solids Concentration in Iron Ore

网页2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and

Contact

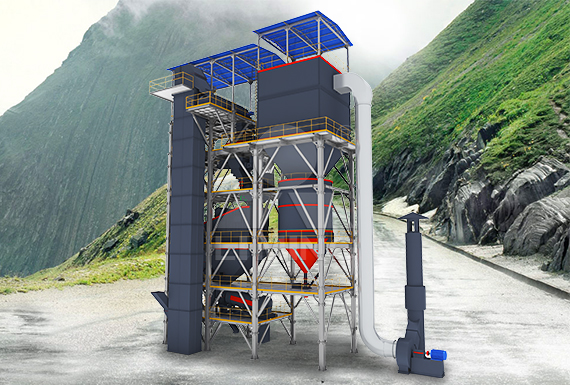

iron ore processing plant, iron ore mining process, iron ore

网页Liaoning 3000t/d Iron Ire Renovation Project. This plant initially used stage grinding single magnetic separation fine screening and regrinding process. Xinhai increased cationic

Contact

Process simulations in mineralogy-based

网页2023年2月13日 This study focussed on flowsheet simulation for mineralogical-based approach to geometallurgy of iron ores. Process

Contact

Treatment of iron ore beneficiation plant process water by

网页2021年1月1日 Table 2 shows the concentrations of various metal ions and other water quality parameters present in process water collected from iron ore beneficiation plant

Contact

Beneficiation Plants and Pelletizing Plants for Utilizing

网页2015年1月27日 1. Iron ore supply and demand outline 1.1 Types of iron ore Iron ores can be classified in different ways. The most important has to do with the iron content. In

Contact

Guide to Standards Iron Ore Mining SAI Global Store

网页2016年11月21日 Iron ore is then transported and shipped to milling plants. This guide provides information on Standards, Certification schemes and other industry specific

Contact

Discrete Event Simulation of an Iron Ore Milling Process

网页2011年9月9日 In this study, a whole processing plant simulation modeling approach is followed. The study focuses on modeling an iron ore magnetic separation processing

Contact

Iron ore grinding millGrinding plants for Iron Ore

网页Iron Ore powder processing technological process. Phrase one: raw material crushing. Iron ore blocks will be crushed to 15mm-50mm fineness by crusher. Phrase two: grinding.

Contact

Crushing Plant Design and Layout Considerations 911

网页2016年2月24日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC MiningMetals,Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to

Contact

Discrete Event Simulation of an Iron Ore Milling Process

网页2011年9月9日 In this study, a whole processing plant simulation modeling approach is followed. The study focuses on modeling an iron ore magnetic separation processing plant in Arena discrete event simulation software (Rockwell Automation). A typical iron ore processing plant, with several comminution and separation stages, is considered for

Contact

Iron Ore Processing, General SpringerLink

网页2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

Contact

Optimization of Solids Concentration in Iron Ore Ball

网页2019年6月18日 pilot plant and full-scale results, which demonstrated the benefit of reducing solids concentration to values between 76 and 80% in weight for the ore of interest from the 83% that was originally used in the operation. Keywords: iron ore; ball mill; modeling; simulation; population balance model; slurry density 1. Introduction

Contact

Treatment of iron ore beneficiation plant process water by

网页2021年1月1日 Table 2 shows the concentrations of various metal ions and other water quality parameters present in process water collected from iron ore beneficiation plant followed by settling and filtration. It is observed from the results that the concentration of total Fe, Cr, Pb, Mn and turbidity are found to be 115.24 mg/L, 7.10 mg/L, 2.68 mg/L, 0.96

Contact

CHAPTER II MINE TAILINGS FACILITIES: OVERVIEW AND

网页2020年9月8日 Ore milled 18 800 000 000 tonnes Ore produced 10 180 000 000 tonnes Tailings 8 850 000 000 tonnes Figure 3. Estimate of the volume of tailings and waste rock produced in 2016 in relationship to ore production (c.f. plastic waste weight and volume) Copper 46% Gold 21% Iron 9% Coal 8% Phosphate 4% Lead zinc 3% Nickel 2%

Contact

Hazard Identification, Risk Assessment, and Control

网页The study was carried out in a 4-m tonne iron ore pelletizing industry located in Odisha, India from March to December 2015. The pellet plant used travelling grate technology to convert low grade fines into value-added pellets. The slurry was received at the pellet plant from the beneficiation plant through a 220-km pipe line.

Contact

Recycling of steel plant mill scale via iron ore sintering plant

网页2022年2月28日 Mill scale is a valuable metallurgical raw material since it contains 65–70% iron. JSW Steel Ltd is a 7 Mtpa integrated steel plant and generates 270 t of mill scale per day. Most of the materials of steel plant wastes are

Contact

2.0MTPY Iron Ore Pelletization Plant

网页2019年6月29日 2.0 MTPY Iron Ore Pellet Plant Feasibility Report for Capacity Enhancement #20, Lakshmi, Shankaramutt Road, Shankarapuram, Basavanagudi, Bangalore 560 004 be no mixing of coke iron ore in the mill feed. c) Boulders in the Iron ore receipt: Receipt of boulders through railway wagons is a common problem. These

Contact

Category Title NFR SNAP 0402 ISIC Version European

网页2019年11月4日 produces blast furnace gas which may then be recovered and transferred from the iron and steel mill to the onsite coke plant and burned within the coke ovens or used in sinter production. 2.1.2 Sinter and pellet production This subsection only addresses travelling grate sintering, which is by far the most important technique for iron ore sintering.

Contact

Guide to Standards Iron Ore Mining SAI Global Store

网页2016年11月21日 Iron ore is then transported and shipped to milling plants. This guide provides information on Standards, Certification schemes and other industry specific information that may be of interest to anyone working within the iron ore mining industry, including information relevant to mining, electrical, and civil/structural

Contact

10 Best Ore Beneficiation Plants for Sale (with Costs)

网页2021年3月24日 38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength Magnetic drum separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

Contact

An Overview: Utilization of Iron Ore Fines and

网页2019年8月5日 The zero-waste technology is developed for recycle and utilization of iron and steel plant wastes.Iron ore fines and coal fines are also generated during mining and transportation. These iron ore

Contact

12.5 Iron And Steel Production US EPA

网页2015年9月10日 12.5.1.2 Iron Production Iron is produced in blast furnaces by the reduction of iron bearing materials with a hot gas. The large, refractory lined furnace is charged through its top with iron as ore, pellets, and/or sinter; flux as limestone, dolomite, and sinter; and coke for fuel. Iron oxides, coke and fluxes react with the

Contact

Recycling of steel plant mill scale via iron ore sintering plant

网页2012年4月1日 These oxides, known as mill scale, occur during continuous casting, reheating and hot rolling operations. Mill scale is a valuable metallurgical raw material since it contains 65‐70% iron. JSW

Contact

Mineral Processing Operating Cost Estimate of

网页2016年9月1日 The roasting cost works out at approximately $1.22 per ton of concentrate, distributed as shown in Table 99. At MacLeod Cockshutt Gold Mines, Ltd., the cost of roasting in 1941- 1942 was 32 cents per ton

Contact

Iron Ore Processing,Crushing,Grinding Plant

网页Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

Contact

KOBELCO Pelletizing Process

网页2011年1月6日 KOBELCO TECHNOLOGY REVIEW NO. 29 DEC. 2010 58 KOBELCO Pelletizing Process Shinichi YAMAGUCHI*1, Takeshi FUJII *1, Norihito YAMAMOTO,Tsutomu NOMURA*2 *1 Plant Engineering Department, Iron Unit Division, Natural ResourcesEngineering Business, *2 TechnologyProcess Engineering Department,

Contact